Decanter centrifuges – Tricanter – Sedicanter – Sorticanter – Disc centrifuges – Belt presses – SX Crud treatment

Belt Presses

FLOTTWEG BELT PRESSES are designed for dewatering slurries where a high capacity and a high cake solids content are required. They are best suited to applications where the solids are compressible, granular, fibrous or cellular in nature. Flottweg’s range of belt presses can reach capacities of up to 22,000 kg/h.

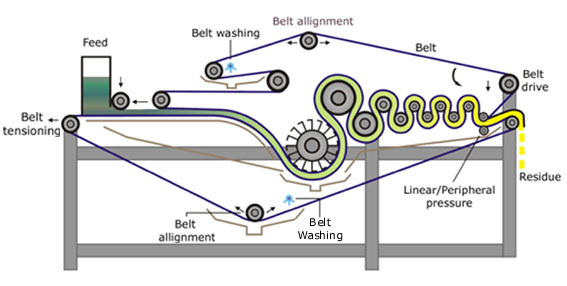

Mode of operation

The belt press operates by applying steadily increasing pressure to the surface of the solids. The solid-liquid mixture is fed continuously to, and distributed even over a continuous belt. The belt then carries the slurry into a downwards orientated wedge zone, which releases the bulk of the liquid. The liquid is extracted by an L-profile roller before the cake is compressed. This compression is achieved by forcing the cake to travel an S-shaped path around 10 press rollers with progressively decreasing diameters. This results in a steadily increasing compressive and shearing force on the cake.

The S-shaped route constantly changes the orientation of the cake, to open up new filtration passages.Additional peripheral rollers can be added to further optimize the compression effect. The cake is removed from the belt by plastic scrapers and the belt is then rinsed by high pressure jets.For slurries with poor dewatering characteristics, the addition of floculants is recommended.

The S-shaped route constantly changes the orientation of the cake, to open up new filtration passages.Additional peripheral rollers can be added to further optimize the compression effect. The cake is removed from the belt by plastic scrapers and the belt is then rinsed by high pressure jets.For slurries with poor dewatering characteristics, the addition of floculants is recommended.

Typical applications

• Dejuicing of fruit pulp

• Mineral sands

• Vegetable mash

• Stillage residues

• Paper pulp and cellulose